YOUR PRODUCT • YOUR PRODUCTION • YOUR PARTNER

As your manufacturing extension, TengFeng empowers you to realize your full potential. Leverage our vertically integrated services to meet your vision and budget.

Selected Categories

Advanced surgical solutions, precision-engineered to empower clinicians and achieve superior patient outcomes.

Ortho Molding Consumables

Surgical Molding Consumables

Gastro Molding Consumables

Why Choose Us

With the mission of "Precision Manufacturing, Safeguarding Health", Tengfeng is committed to providing high-quality injection molding and assembly integrated solutions for global medical industry customers.

High-tech Enterprise

A national high-tech enterprise, specializing in the research and development, production and manufacturing of medical consumables, with strong technical strength.

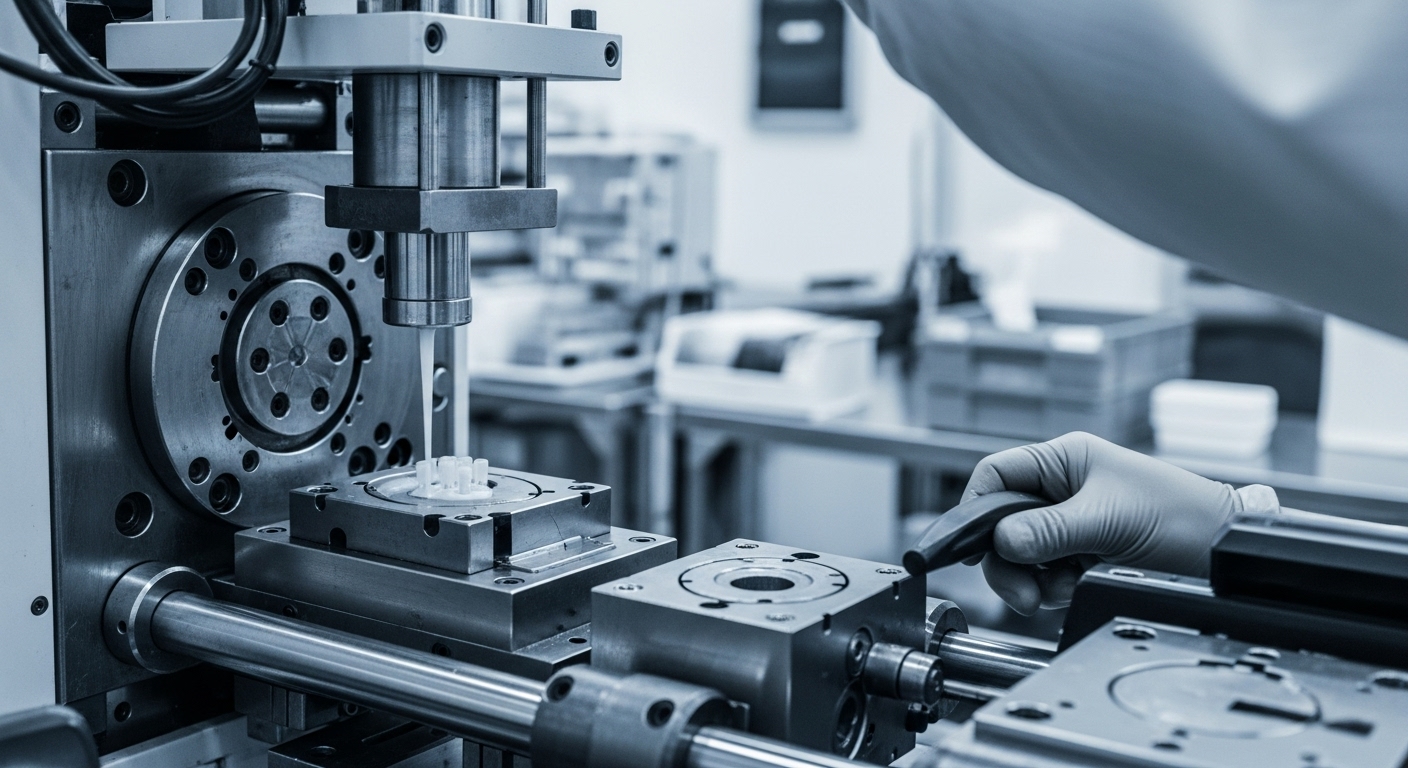

Modern Facilities

It has a modern injection molding workshop, a precision mold center and a 100,000-level clean production environment.

Advanced Technology

The company has advanced injection molding technology and automated assembly technology.

Quality Management

Passed ISO 9001 and ISO 13485 certifications, and established a complete quality control system.

Global Services

Committed to serving customers in the global medical industry, our products are sold far and wide in domestic and overseas markets.

Customized Solutions

Persist in technological innovation and promote the high-quality development of the medical consumables industry through cooperation among industry, academia and research.

Medical Plastic Injection Molding Capabilities

We specialize in high-precision medical injection molding, supported by advanced equipment and a highly skilled team. With a strong commitment to quality, efficiency, and innovation, we provide reliable manufacturing solutions that support our clients' success in the global medical market.

Product Quality Guarantee

We use electronic vision and inspection systems to ensure the quality of parts is maintained.

Read MoreManufacturing Of Medical Consumables

Focusing on the research and development and manufacturing of medical consumables products, we provide high-quality injection molding and assembly integrated solutions.

Quality Control System

Establish a complete quality control system, obtain international standard certification, and ensure that products meet the strict requirements of the medical industry.

Technological Innovation Ability

We have always adhered to technological innovation, promoting the high-quality development of the medical consumables industry through technological upgrading and cooperation among industry, academia and research.

Quality and Environmental Certification

We are committed to continuously improving the effectiveness of our quality system and providing products and services that meet the requirements and expectations of our customers.